In the process of cementing and hydraulic fracturing, the

swivel joints is one of the main parts connecting cement trucks and wellheads. With this movable elbow, the lines can be joined to each other at any angle, while the movable elbow can absorb most of the vibrations due to uneven pumping.

The damping effect of the movable elbow puts special requirements on its components such as bearings and seal rings. The flexibility and strength of the active elbow stub and the elbow must be considered together. In order to increase the life and reliability of the movable elbow, the bearing seal must be improved.

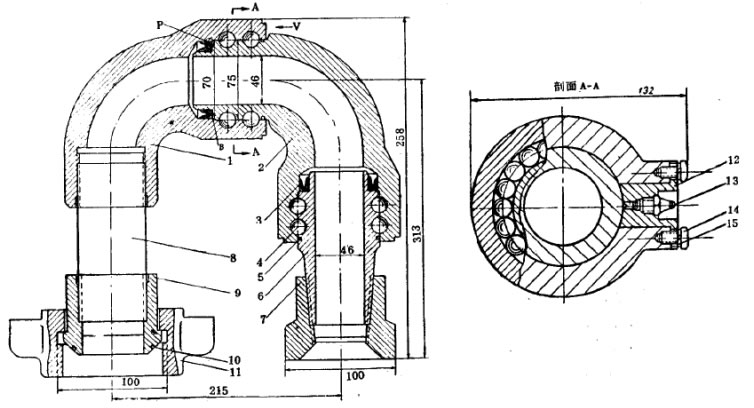

Figure 1 is the

swivel jointsof the new orange structure. In order to make the sealing ring more tightly attached to the sealing surface, the position of the oblique opening of the packing is shifted by 90° than that of the ordinary movable bending. This causes the oblique opening to face the direction of the flow. When the elongation is 1 meter, the oblique opening becomes softer, so that the packing can be sealed under a small pressure (20-50 kg/cm 2 ).

1-wire buckle elbow; 2-bend tube; 3-plate root; 4- diameter 10 mm ball; 5-sealing ring; 6-bushing; 7-conical seat; 8; short tube; Vertebral body 10 - sealing ring; 11 - outer casing nut; 12 - plug cover; 13 - grease mouth; 14 - bolt; 15 - spring pad.

These measures reduce the likelihood that abrasive debris will fall into the gap between the packing and the contact surface.

It was observed during the use of the movable elbow that the outer diameter of the seal ring was the fastest at the part of the part P (Fig. 1). The packing starts to move toward the gap B when the pressure is high, and is quickly stabbed in the portion of the part P.

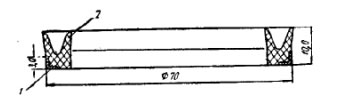

To prevent sprinting, the packing is assembled with a metal ring 1 (Fig. 2). The ring is stamped from a 0.5 mm thick steel plate and placed in a mill to be formed by pouring rubber.

1-ring; 2-rubber

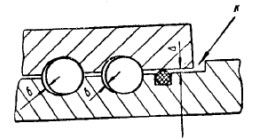

In order to reduce the entry of dirt from the end face (direction of the V arrow) into the bearing, a rubber seal ring is placed in front of the bearing to protect the dirt from entering the bearing until the bearing wears. When 6 gaps are formed between the ball and the bearing groove (Fig. 3), if the vibration is large, the dirt enters the Δ gap between the connecting parts and penetrates into the bearing, as indicated by the K arrow (Fig. 3). Therefore, it is not possible to completely prevent dirt from entering the bearing. In order to remove the dirt from the bearing after work and to keep the bearing properly lubricated, there is a hole in the cover 12 and the grease fitting 13 is provided. The fresh lubricating oil is injected into the bearing through the grease fitting through the grease fitting to discharge the dirt. In this way, the lubrication of the bearing can be restored after each work to increase the service life of the

swivel joints.

Figure 3 active elbow sealing packing